| Sign In | Join Free | My carsrow.com |

|

- Home

- Products

- About Us

- Quality Control

- Contact Us

- Get Quotations

| Sign In | Join Free | My carsrow.com |

|

Brand Name : Waylead

Model Number : WL-620

Certification : /

Place of Origin : Shanghai

MOQ : 1

Price : 1 -10pcs, USD17000

Payment Terms : L/C,T/T,Western Union

Supply Ability : 300 sets per year

Delivery Time : 30 days

Packaging Details : International standard packaging for shipping

Packing Speed : 10-50bags/min

Model : WL-620

Packaging Size : Customizable

Packaging Material : Plastic, Paper,

Product Type : Packing Machine

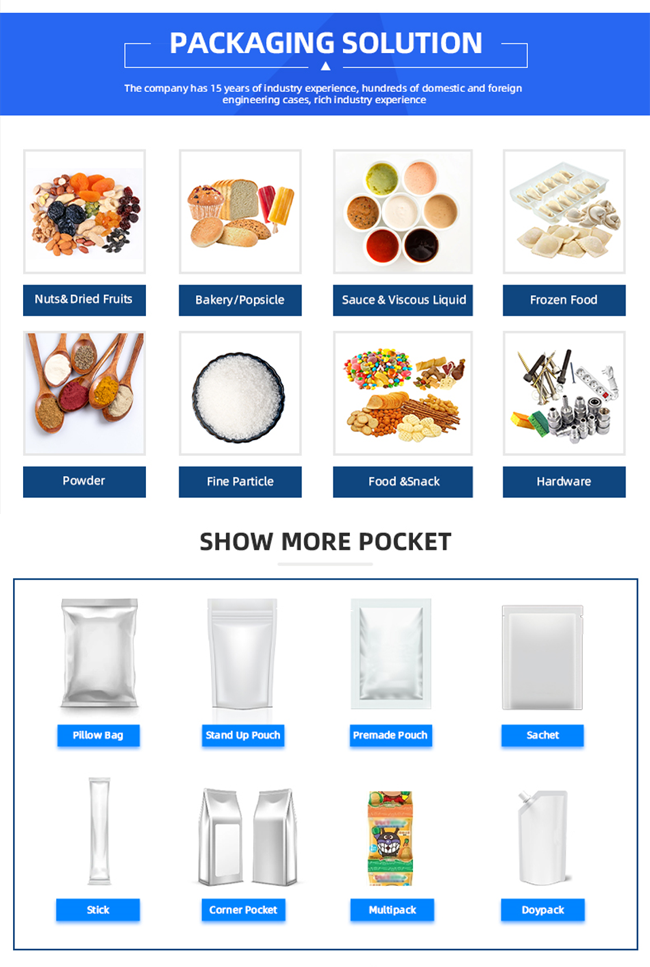

Application : Food Beverage Commodity Chemical Machinery & Hardware

Power Type : Electric

Power Consumption : 3.5 KW

Material : Stianless Steel

Packaging range : Granules Powder Liquid

The VFFS machine operates around a top-down material flow and film forming process, precisely controlled by an electronic system. The steps are clear, continuous, and highly efficient. A breakdown is as follows:

1. Film Supply and Vertical Forming: Creating a Closed Packaging Chamber

Rolled packaging films (PE film, composite film, aluminum foil film, etc.) are drawn out through a film reel, and tension is adjusted by guide rollers and a tension controller to ensure smooth, wrinkle-free film transport.

The film enters the vertical forming unit (core component), where it is folded into a tubular structure along the unit's contour. Simultaneously, a side-sealing mechanism (heat sealing or ultrasonic sealing) longitudinally seals both edges of the film, forming a closed "packaging tube" with an open bottom and a continuous top, preparing for subsequent material filling.

An optional coding device can be added to simultaneously print production date, batch number, specifications, and other information before film forming, ensuring packaging traceability.

2. Material Metering and Precise Filling: On-Demand Injection into Packaging Tubes

Materials to be packaged (granules, powders, liquids, sauces, etc.) enter the metering device through the hopper, where precise metering is completed according to preset specifications (metering methods adapt to material types):

Granular/lumpy materials (e.g., nuts, candy): Volumetric metering cups or electronic weighing;

Powders (e.g., flour, milk powder): Screw metering or screw filling;

Liquids/Sauces (e.g., cooking oil, salad dressing): Piston metering or flow metering;

The metered material is vertically injected into the pre-formed tubular packaging film below through the feed pipe. The filling process is synchronized with the film conveying speed to avoid material spillage or excessive voids inside the packaging tube.

3. Bottom Sealing and Separation: Forming Independent Packaging Units

Once the material inside the packaging tube reaches the preset amount, the film moves downwards with the traction mechanism to the horizontal sealing and cutting mechanism.

The horizontal sealing and cutting blade simultaneously completes two key actions: ① Bottom heat sealing: sealing the bottom of the packaging tube to prevent material leakage; ② Top sealing and cutting: completing the top sealing between two adjacent packages (i.e., bottom sealing of the next package) and precisely cutting to separate individual packaged finished products.

High-end models are equipped with photoelectric sensors and a "no material, no sealing" function. If unfilled material or abnormal metering is detected, sealing and cutting will automatically stop to avoid wasting empty packages.

4. Finished Product Output: Completing the Packaging Process

The sealed and cut finished products are conveyed to the next stage (such as weighing and boxing) via an output conveyor belt. Some models can be equipped with a shaping device to ensure that the packaged finished products are neat and aesthetically pleasing.

| Model | WL-220 | WL-320 | WL-420 | WL-520 | WL-620 | WL-720 |

|---|---|---|---|---|---|---|

| Packing Speed | 10-80bags/min | 10-100bags/min | 10-90bags/min | 10-70bags/min | 10-50bags/min | 10-40bags/min |

| Packaging Type | Bags Film Foil Pouch | |||||

| Degree of Automation | Automatic | |||||

| Application | Food Beverage Commodity Chemical Machinery & Hardware | |||||

| Power Type | Electric | |||||

| Type of power supply | 380V | 380V | 380V | 380V | 380V | 380V |

| General power | 3.9 KW | 3.2KW | 3.5KW | 3.5KW | 3.5KW | 4KW |

| Weight | 350 kg | 350kg | 500kg | 550kg | 700kg | 800kg |

| Dimension | 1350X1100X1000mm | 1320X980X1180mm | 1350X1065X1450mm | 1365X1160X1550mm | 1600X1400X1900mm | 1650X1400X2080mm |

Based on the industrial attributes and application requirements of VFFS packaging machines, their four core competitive advantages typically focus on efficiency, adaptability, safety, and economy, specifically as follows:

Highly Efficient Integrated Operation: Integrates bag making, metering, filling, and sealing into one unit, eliminating the need for additional equipment, significantly shortening the packaging process, and adapting to industrial-grade continuous production.

Strong Product and Specification Adaptability: Supports multiple product forms such as granules, powders, and liquids, with flexible adjustments to bag types (e.g., three-side seal, four-side seal) and sizes to meet diverse packaging needs.

Safety, Freshness Preservation, and Compliance: Precision sealing technology blocks oxygen and moisture, extending shelf life; contact parts comply with FDA/GMP standards, adapting to high-safety-requirement scenarios such as food and pharmaceuticals.

Cost and Resource Optimization: On-demand bag making reduces packaging material waste, automated operation lowers labor costs, and improves production cost-effectiveness.

|

|

High Speed WL-620 Vertical Form Fill Seal Machine with 10-50bags/min and 3.5 KW Electric Power Images |